One of the most frequent topics of conversation that comes up in my shop is the differences in rifle actions and which one is the best.

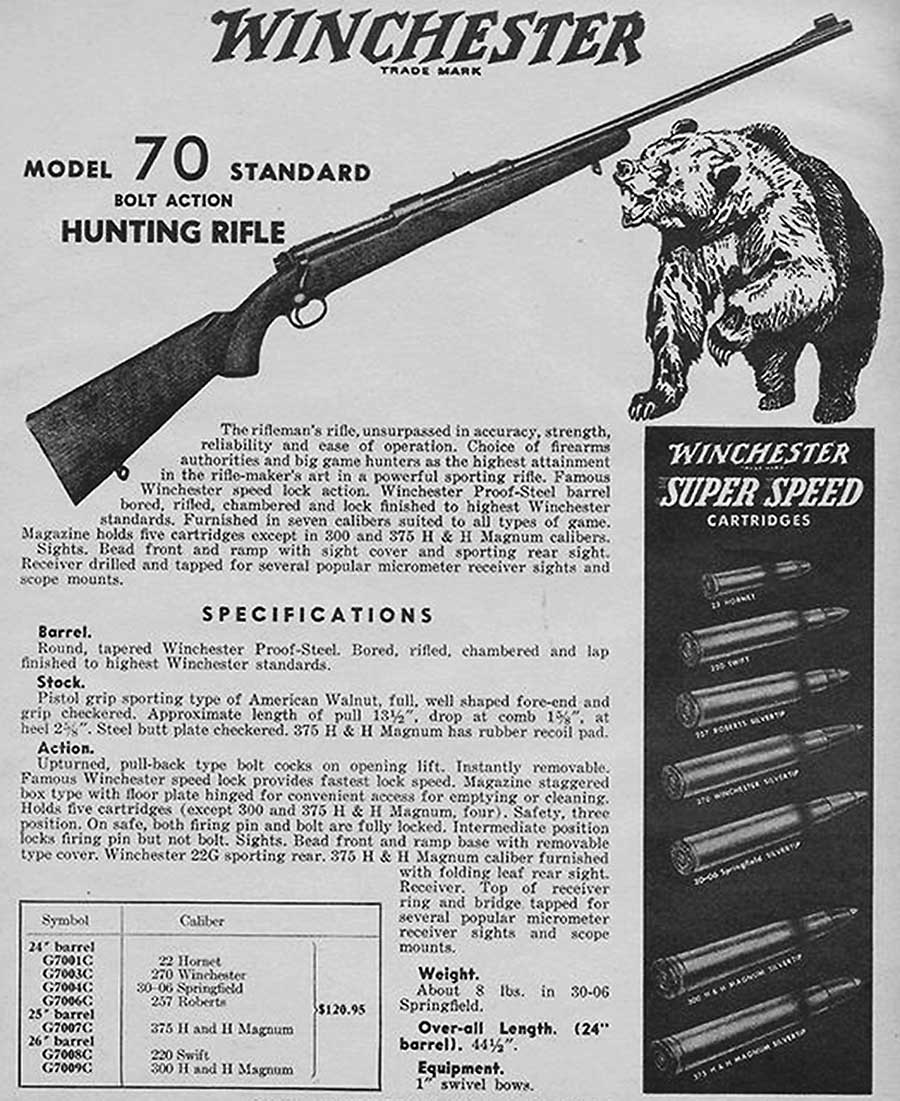

Although, like most things, there is not truly a “best,” I’ll tell you right now that if all I could possess is variations of the Winchester Model 70, the “Rifleman’s rifle,” I could get by handily.

The first version of this weapon came out in 1936 as a major upgrade of their model 54. (The Model 54 was a blatant rip-off, but not an exact copy, of the German Mauser). This rifle has become legendary as the pre-’64 version. It has such desirable qualities as a fixed ejector, non-rotating claw extractor and a three-position safety.

That “fixed ejector” part of the description is kind of misleading as the ejector actually rotates on a retaining/pivot pin down out of the way of the bolt as it is run forward. It then pops up into a notch in the bolt body and face as the bolt is drawn to the rear. If there is a live or fired round on the bolt face, carried by the extractor, it will eject from the rifle’s ejection port in direct relation to how hard the bolt is yanked back.

This is a nice feature for reliability, but also just for general shooting since you don’t have to chase your casings down if you pull the bolt back gently and either drop the empties at your feet or on the shooting bench. If pulled back violently, you can send the ejecta into orbit.

The claw extractor is much like the name suggests. There is a long spring loaded claw alongside the bolt body and around the side of the bolt face that holds the casing against it. As the bolt is moved forward the cartridge case’s rim is picked up by the bolt’s face. The rim slides up it smoothly and is held there at all times. This makes the rifle impossible to jam by “short stroking,” as can happen with other rifles, or by creating a double feed.

The rifle can also be fed and fired at any angle, even upside-down. These features put the pre-’64’s reliability second to none.

Upon learning this, many gun afficionados are somewhat surprised to learn that there might be something to this “pre-’64 thing” rifle nuts talk about after all.

You may be wondering what happened in 1964 that made such a monumental difference at Winchester.

Remington had brought out the Model 700 in 1962. It was cheaper to produce and sell and the management at Winchester/Olin at the time perceived a need to “keep up” with their competition: “Big Green.”

So the bean counters went about destroying just about everything that made the Model 70 a Model 70.

First, they took away the fixed ejector and saddled it with the plunger-type ejector of the competition. Like all rifles with a plunger ejector, it is very possible to get one of these plungers hopelessly stuck into its blind hole in the bolt face. When that happens, expect an unpleasant or horrendous repair bill.

Nevertheless, most centerfire bolt-action firearms have this type of ejector that simply always spring loads the case towards the ejection port side of the rifle.

As soon as the forward most portion of the loaded or empty cartridge clears the front receiver ring, it is flung out of the action, hopefully forcefully, every time.

There is no control by the shooter of the speed or force at which it ejects. This type of ejector totally eliminates the possibility of having controlled-round-feed like the pre-’64 version. These actions are called push-feed actions, as they simply push the shell forward of the bolt face, ejector and extractor until it is fully seated in the chamber, the ejector is pushed into its blind hole in the bolt face and the much smaller sliding extractor is snapped over the rim of the shell casing.

The classic-style walnut stock with real cut checkering was also replaced with quite an ugly piece marred with cheap pressed in “checkering” and a barrel that was free-floated so much you could throw a cat between the barrel and fore-end.

To be fair, they shot pretty well, partially because of that free-floated barrel. They also accomplished their goal of making a comparable rifle to the 700 Remington as that rifle also had a plunger ejector and press-checkered stock.

The Model 70 still had one advantage over the Remington in that most Remington centerfire rifles have the worst extractor ever put into a rifle.

The post-’64 Winchester’s isn’t as good as the pre-’64/Mauser style but it’s better than the Remington, with its questionable advantage of “three rings of steel.”

There was one shining success in Winchester’s push-feed models and that was the Heavy Varmint version made in the mid to late ’90s. With an excellent synthetic stock containing a full aluminum bedding block and a superbly accurate stainless steel heavy barrel, they were shootin’ machines with accuracy equal to any massed-produced rifle to date.

There were other rifles of the post-’64 variety that were quite good, as the quality drastically improved throughout its production run, such as the well-finished XTRs and the very comely Featherweights with their classic cut checkering and schnable forend. These rifles brought Winchester back to the forefront of American rifle manufacturers.

In late 1982 the rights to use the Winchester name were sold by Olin Corporation to U.S. Repeating Arms Company or USRAC. Olin kept the ammunition manufacturing side of things and USRAC started making the rifles and shotguns.

This part is a little blurry to me, but somewhere along the line, I think in the early 1990s, Fabrique Nationale (FN) of Belgium bought USRAC. They already owned Browning. As they got more heavily involved in “Winchester,” they made the exceedingly wise decision to start building the pre-’64 type action/rifle again. Kudos!

At first it was a limited production “Custom Shop” offering. Somewhere around 1994 that changed into a gradual, virtual over-taking of the whole line, since there were now substantially more “Classic,” as they were called, versions than push feeds. The push feeds were regulated to varmint/target and the budget-priced versions of the Model 70.

The only real difference between the pre-’64 and Classic is that the newer rifle didn’t retain the coned breech of the later rifle. The pre-’64 had a taper inward at the breech end of the barrel that was like a funnel, which aided in feeding.

It was a costly feature to add to the rifle, so it was left off of the newer Classic. It wasn’t deemed necessary as it was not used on the push-feed rifles and they had been feeding fine for decades. Still, it was a nice feature.

When USRAC, Winchester/Olin and Browning jointly brought out the Short Magnums and, later, the Super Short Magnums, USRAC brought forth another variation of the vaunted Model 70: the Controlled Round-Push Feed. At first this sounds like an oxymoron, but what they brilliantly did was combine the controlled-round-feed of the pre-’64/Classic made possible by those action’s fixed ejector and the rotating sliding extractor of the post ‘64 rifle. It was a match made in Heaven for a varmint hunter.

You now had the ability to lazily drop empty cases right beside you on the bench rest with a light touch on the withdrawal of them from the breech and the ability to singly load shells into the chamber without running them through the magazine. (Although a claw-extractor action will allow you to single feed rounds this same way, it is not advisable as it is harder on the extractor to do so.) These short and super-short actions also have a faster lock time (the amount of time, measured in milliseconds, it takes from the time you pull the trigger to when the tip of the firing pin actually sets off the primer) than their longer brothers, which also aids accuracy.

The last significant advantage of all Model 70s is the three-position safety.

Many people have sluffed this off as inconsequential, but it most certainly is a major advantage. As the most obvious one to most gun owners that are even cursorily familiar with it, there is a fully forward position to the safety lever that allows the rifle to be fired. A middle position allows the bolt to be operated with the safety on, which facilitates the removal of a live round from the chamber in complete safety since the striker/firing pin is completely locked and moved back off of contact with the trigger.

That locking of the striker is one of the hidden secrets of the design.

Most rifles’ safeties simply act on the trigger system and keep the trigger from being pulled. Locking the instrument of detonation of the cartridge (which is the striker/firing pin) is MUCH safer.

Yet another advantage to this safety system is almost completely unknown. If the bolt is closed on an empty chamber, the safety is placed in this middle position and the bolt is withdrawn from the rifle by simply pressing in on the bolt head lock on the left side (for a right-handed rifle) the striker system can be completely removed from the bolt body for inspection and/or cleaning.

There are virtually NO other rifles which have this feature/capability.

The third position also has a major advantage most hunters don’t think about until it comes to haunt them on a hunt. In this rear-most position the striker is blocked just like in the middle position but the bolt is also locked down in this position, it cannot be opened.

Many rifles, in this time of rampant litigation, allow the bolt to be opened with the safety on. That’s all fine and dandy and so does the Winchester, but only in the MIDDLE position. Most other rifles, save the Savage 110 series and newer Weatherby Vanguards, only have two positions to their safeties: fire and safe.

The average hunter steps out of his vehicle, loads a round in the chamber of his rifle and puts the safety on. Great, so far. Then, somewhere along the line, the rifle gets cumbersome to carry, so he/she slings it over his/her shoulder. Many times the bolt handle will snag on something like clothing, brush or a pack and lift part way.

Then, when the hunter least expects it, the intended quarry jumps up and runs at a speed slightly slower than that of sound. Our hero keeps him/herself under control long enough to flip off the safety, take careful aim and squeeze the trigger and … “clunk” will be heard, followed by confusion, various expletives, or both.

All of the striker’s energy that was imparted by its spring was used to rotate the bolt back down into battery and there was none left to set off the cartridge. If you think this possibility is too remote to take into consideration, I invite you to spend a week in my shop and see if you don’t hear a version of this story told.

The rifleman who carries a Model 70 with the safety in the rear-most position will never have this happen to him.

A few years ago the production of the Model 70 and ‘94 was brought to a halt. The machinery was said to be wearing out and breaking down.

Shooters everywhere mourned the loss of these two great icons and went about paying crazy sums for Pre-’64s and Classics. The lesser thought of push feeds was largely ignored. Luckily, that situation was temporary and now the Model 70 is again being manufactured at the FN plant in South Carolina, which makes the machine guns and assault rifles (only full automatics are truly assault rifles) our soldiers are using today.

The new version is said to have tighter tolerances, but honestly I can’t tell any difference. I’ve only ever had one Model 70 through my doors that had a real manufacturing defect and it was fairly easily repaired.

The SC manufactured rifles do, however, have a newer-style trigger system. I MUCH prefer the older one; it was very simple, dead-reliable and easy to tune to perfection most of the time.

As an added bit of clarity: Some of the newer rifles only have the FN/Browning/Winchester Utah facility stamped on them, but I believe they are still actually manufactured in SC.

I remember a gun writer in my youth who said of the switch to the cheaper post-’64 Model 70, “It never occurred to the idiots to leave the rifle alone and simply charge more for it.”

As the shooting/hunting/collecting public has proven over the last 46 years, he was most definitely right.

That statement was in the 1984 annual edition of the GUN DIGEST, the first gun book I ever received. My mom bought it for me when I was about 11 years old. It was on the closeout table at the Lebanon Payless store.

That book started me along the line that my professional life has taken, in turning my hobby into my career, and I often wonder if my mom regrets buying it. I read it front to back about a hundred times and then proceeded to try to fill my room with any firearms-related publication I could beg, borrow or buy.

I have to agree with the thousands of others and say: “Make mine a Model 70!”

– Jeff Hutchins writes occasionally about firearms-related topics for The New Era. He operates Rangemaster Gunworks at 1144 Tangent St. in Lebanon.