Two years ago, agriculture teacher Mike Wilson was feeling excited about a new project at Lebanon High School’s Land Lab.

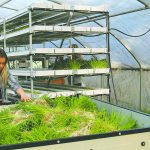

He’d just received a grant to purchase a hydroponic fodder growing system that would allow him and his students to grow their own feed in a greenhouse year-round.

Since then, he’s added a second, larger system, tripling the amount of fodder they can grow and reducing the amount of feed cost for cows and sheep by about 90 percent, Wilson said.

Wilson first got the idea for the fodder system from an agriculture teacher up in north Clackamas. He said it piqued his interest, so he spent a few days with another agriculture instructor, Lyman Hagen, now retired in Chico, Calif., to learn more.

“One of the benefits of feeding fodder is that it is enzyme-rich and therefore complements the dry forage which is necessary for fiber, especially in ruminant digestion,” Hagen said in an email.

Hagen also noted that the hydroponic system uses considerably less water than pasture-grown grass.

California State University in Chico uses an 8-foot by 16-foot insulated box that produces 1,100 pounds of fodder per day using approximately 300 gallons of water, he said. In 30 days, that relatively small box produces 16.5 tons of fodder, whereas it would require two acres of land to grow 16.5 tons of alfalfa.

“If feeding fodder to a horse that eats 20 pounds of alfalfa per day, it would require 1,740 gallons of water to grow that 20 pounds of alfalfa,” he said. “Think about how much water we would save if we feed 20 pounds of fodder and 10 pounds of grass hay to a horse or beef cow or dairy cow.”

Wilson needs only a fraction of what the university grows. His hydroponic system produces 300 pounds of barley fodder a day, but it’s still a hefty number considering livestock feed is the biggest cost at the land lab. It’s enough to feed their sheep and 10 cows, although commercial grain and grass hay is still used to supplement the diet.

“It reduces our feed cost dramatically,” he said. “We get a lot of hay donated, but also spent quite a bit of money on baled alfalfa every year.”

Another grant last year provided him the opportunity to purchase a cart and ATV that helps transport the massive load of fodder, which grows in less than a week.

“It goes from seed to feed in six days,” he said. “When you see it go from that seed to that green foliage in a week’s time, that’s just cool.”

The trays are set vertically in six rows, and small tubes feed water into the trays every two hours. Every day, one row of fodder is harvested and replaced with new seed.

Wilson said the work is a little labor intensive, but worth it. One pound of seed can grow five pounds of barley fodder. Plus it’s a unique and good experience for the students, he noted.

The trays have to be scrubbed and bleached, and seed has to soak overnight before placement in the watering system. In the morning, a couple of students lift out 300 pounds of fodder in chunks, place them in the cart, and drive it over to the animals.

Once Wilson had the fodder system well under way, he was able to begin growing their own seed as well.

An alumnus had grown a small patch of seed for them last summer, which was harvested and used to grow more seed. From that, Wilson produced 700 tons of seed, he said. He expects it to last them about a year with the hydroponic system, with some of it reserved for a new harvest of seed production this fall.

“We grew our own seed this last summer, so we have zero cost in the seed this year,” he said. “When we first started this, we were buying barley seed at about $300 a ton.”

The hydroponic system is used most of the year, but does not thrive when temperatures in the greenhouse reach 80 degrees or higher, he said. By then, however, fresh feed is ready for consumption out in pasture.

Prior to the hydroponic system, they were feeding baled alfalfa, which he said is a great feed but very expensive. The barley fodder is like having fresh spring grass year-round, except it’s more nutritious because barley has more protein than the pasture grass. Although alfalfa has a little bit more protein, the fodder has more total digestible nutrients because it’s fresh.

Still, commercial grain and hay need to be purchased to round out the diet.

“This stuff has so much moisture in it that you have to add some long stem dry fiber-like grass hay to their diet. Otherwise, this just goes through them so fast because of the moisture content that they don’t utilize the nutrition in this.”

This past winter, Wilson realized the barley fodder system didn’t work as well for the sheep as he’d have liked. After some research, he decided the winter feed for sheep needs to consist of more grain product so they can get the amount of fat content they need.

The sheep don’t care for it as much as the cows do, anyway.

“The cows just love it; they really go to town on it.”